Posted by Chris Sullivan on Friday, 06 June 2014 at 14:58:59

Filed under: Products, Case Studies

Bob Noakes of Norfolk County Council, Howard Cooke of Asphalt Reinforcement Services and Chris Sullivan of Material Edge visited a variety of sites to see the Dutch experience of the long term performance of GridSeal®.

System Properties

GridSeal® is a composite reinforcing system developed by Ooms Avenhorn Holding bv, consisting of GlasGrid® glassfibre reinforcement mesh and a hot sprayed Sam-C® membrane of SBS polymer modified bitumen. Depending on the circumstances GlasGrid® is covered with 1.0 to 2.5kg/sq.m of hot sprayed Sealoflex®-SC 4 and then treated with approximately 7kg/sq.m. of clean crushed aggregate.

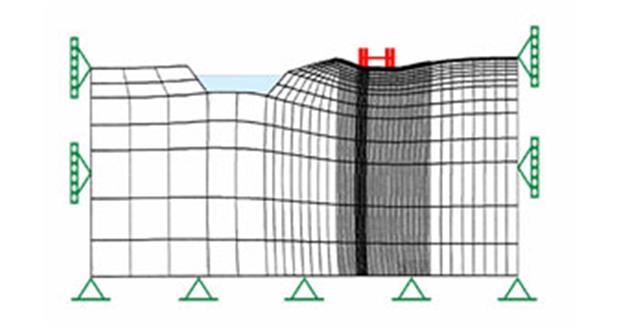

Modelling loading on peat roads

Benefits of Gridseal®

GridSeal® provides improved protection against reflective cracking; excellent and durable visco elastic bond between the existing pavement and the new overlay; durable and tough anchorage of the reinforcement giving increased performance; superior interlock; durable waterproofing of the underlying pavement structure.

Site Visits

The first site visit was to the N99, in the area of Den Helder a 50 years old concrete road overlaid with GridSeal® and Sealoflex® asphalt in 1993. The pavement structure is 18 cm concrete, Sealoflex asphalt levelling course, GridSeal consisting of GlasGrid 8501 and 2.5 kg/m2 Sealoflex®-SC 4, 4 cm dense asphalt concrete and 5 cm porous asphalt.

This site was like many others in The Netherlands boarded on 2 sides by water. On the north side the road runs parallel with a cycle path which is next to a 4metre high dyke behind which is the North Sea. On the south side the road forms the embankment and 1metre below is polder land with irrigation and drainage channels. The road structure therefore is surrounded by and founded on water.

The GridSeal® was chosen in this location for its ability to prevent reflective cracking from settlement cracking which occurs in the pavement structure as a result of swelling and shrinkage during winter and summer conditions. The combination of GlasGrid® reinforcement for strength and Sealoflex® SC 4 for waterproofing has performed admirably with no obvious cracking appearing along the treated section. Sealoflex® in the surfacing layers has prevented any rutting as well as keeping the surfacing durable and crack free. The road texture is still excellent and intervention through overlay has not been necessary during the 12 year life. The pavement looked as if it would last another 12 years without maintenance being required.

On the following day the group visited Mr. Nills Strijbos of Hoogheemraadschap Hollands Noorderkwartier in the area of Amsterdam where he together with Ruud Talsma of Ooms Construction bv showed on their area maps the variety and scope of sites now using Gridseal® for more than 10 years. Mr. Strijbos explained that all of the fully flexible highways in his area which are subject to settlements due to water movement have in the past been heavily patched every 2-5 years. However where GridSeal® is used lifetimes of 8 to 10 years plus are common. All new sites which are in areas subject to settlement are now provided with GridSeal® treatment to prevent premature failure.

There then followed a series of site visits including to one site where GlasGrid® reinforcement alone had been used in the early days and which was showing earlier signs of deterioration than the GridSeal® combination sites.

In addition some failed sites were visited to show the type of failure that occurred where GridSeal® is not used. These failures were similar to many of the peat and fen road sites seen in the UK and Ireland which was of particular interest to Bob Noakes for the areas of England around Norfolk and Suffolk where there are many similar problems encountered.

One particular site where trees were along one side on a small embankment which dropped into drainage channels there were signs of cracking. This was thought to be due to the excessive water demands of the trees and patching using GridSeal® had been performed in those areas with great success.

All told the history of use of GridSeal® was one of success and Mr. Strijbos intended to use the system for a long time to come.

Tags: gridseal, dutch

Posted by Chris Sullivan on Friday, 30 May 2014 at 10:00:24

Filed under: Products, Case Studies

The use of asphalt to generate solar heated water to defrost roads is an excellent subject for NCE to bring to the attention of your readers. In addition to the TRL trials using soil as the medium of storage (Trials begin on salt free road de icing system NCE last week) there is already a commercially available system being used in The Netherlands which utilises ground water in aquifers for storage of hot and cold water.

The first 2 Road Energy System® projects (as the Dutch process is called) in the UK are now imminently being constructed in Scotland by a soon to be signed UK licensee. A national surfacing contractor has also expressed interest in the system which utilises low temperature polymer modified asphalts to avoid melting the European patented plastic pipes and retaining grid system.

Undoubtedly interest will continue to grow when people fully realise the scope for generating heat and cold from asphalt pavements.

The Road Energy System® was developed jointly by a multi discipline engineering team comprising Ooms Avenhorn Holding (contractor), Tipspit and Vloerverwarming as a method for heating and cooling buildings. Following this process the ‘waste’ warm and cold water still has sufficient energy to defrost in winter roads, car parks, ramps, flyovers, aircraft standing and taxiways etc as well as cooling them during summer, thus prolonging the life of the pavement into the bargain. The system has successfully passed through extensive trials and developments over the last 8 years to reach major scheme status. The largest project to date at 10,000sq.m. is a flyover into Rotherdam docks where defrosting of the elevated structure is key to ensuring year round access.

Now that authorities and clients are looking to new housing, airport and industrial developments to be carbon neutral in terms of environmental impact the Road Energy System® provides a viable proven solution to low energy heating and cooling of buildings. Forward looking councils like Dundee have already identified schemes where the system maybe used in future. Airport authorities have also expressed interest with acres of black surfacing to utilise for collecting energy, which also require defrosting in winter, and large terminal buildings to heat and cool.

With NCE’s talent to reach the masses we would be delighted to show your readers real European cooperation involving multi disciplined engineering teams on UK based working projects in the near future.

Chris Sullivan I Eng.,M.I.H.T.

Managing Director

Material Edge Ltd

Tags: salt, trials