Posted by Chris Sullivan on Friday, 05 June 2020 at 06:46:31

Filed under: Products, Case Studies

New Bridges product Section

Be sure to check out our new bridge products below!

Tags: bridges

Posted by Chris Sullivan on Friday, 05 June 2020 at 06:12:43

Filed under: Products, Case Studies

Waterproofing Asphalt system on Rose Fitzgerald Kennedy Bridge, Ireland

Paper and presentation from March 2020 Highways and Airport Pavement Engineering Conference, Liverpool John Moore University (LJMU).

Read the paper here

Tags: asphalt, bridge

Posted by Chris Sullivan on Wednesday, 03 October 2018 at 18:27:34

Filed under: Products

RoofBond® Stretch 60

RoofBond Stretch 60 and is used as a Lead free flashing on Chimneys, around rooflights and even on corrugated or "wrinkly tin" roofs.

Read more about RoofBond® Stretch 60

Please contact us for more information or a full quotation.

Tags: roofbond

Posted by Chris Sullivan on Wednesday, 06 December 2017 at 11:26:26

Filed under: Products, Services

SolarRoad is an innovation for the here and now!

Created by a consortium of companies including Ooms, this unique Solar Energy from a light vehicle trafficked pavement system is now successfully generating electricity in The Netherlands and France and is available to a town near you soon!

The SolarRoad system is ideally used coupled with battery storage where there is no access to the electricity grid but lighting and electrical energy are vital such as in: National Parks, Water sport centres and other outdoor pursuit centres.

SolarRoad is entirely non polluting in its generation of electricity and requires only an annual inspection with no ongoing maintenance even in the wilds of our countryside.

Step by step Installation Guide and product only pricing is now available on request for the UK and Ireland.

Read more about SolarRoad

Please contact us for more information or a full quotation.

Tags: solar, road

Posted by Chris Sullivan on Friday, 12 June 2015 at 13:42:35

Filed under: Bitumen

A new primary school in Hampshire has applied over 1500 square metres of Bituchem's Natratex Cotswold to its playground and outdoor teaching areas.

Berewood Primary School accomodates children aged four to eleven.The Natratex Cotswold material was specified in buff as it was considered more attractive than black tarmac but still smooth enough to be safe for young children to play on.

Read the full article here.

Tags: playground

Posted by Chris Sullivan on Friday, 13 June 2014 at 14:59:13

Filed under: Products, Case Studies

Sealoflex Combination – 9 Years and Counting – 2005 Debut in UK Car Parks Revisited

July 2005 saw the start of a contract to lay approximately 50,000m² of GridSeal® at London’s Heathrow airport on the Pink Elephant Car Park, reputedly the largest car park in Europe.

This is the first use in the UK of GridSeal®, a combination of GlasGrid® and Sealoflex SC-33, a system that has been successfully used to reduce reflective cracking in asphalt overlays throughout Europe, the Middle East, Far East and Australia since 1990.

Consultants Project Techniques were faced with a common difficulty of providing a thin flexible overlay system over a concrete base with the client’s requirement to minimise reflective cracking. The system chosen after in depth technical consultations and fierce competition was GridSeal® which is a combination of GlasGrid® 8550 with tensile strength 50kN/m in each direction and Sealoflex SC-33 a hot sprayed polymer modified binder at 1.7kg/m² rate of spread. This combination is finally overlaid with 10mm chippings to keep paving traffic aware from the highly adhesive binder layer.

Consultants Project Techniques were faced with a common difficulty of providing a thin flexible overlay system over a concrete base with the client’s requirement to minimise reflective cracking. The system chosen after in depth technical consultations and fierce competition was GridSeal® which is a combination of GlasGrid® 8550 with tensile strength 50kN/m in each direction and Sealoflex SC-33 a hot sprayed polymer modified binder at 1.7kg/m² rate of spread. This combination is finally overlaid with 10mm chippings to keep paving traffic aware from the highly adhesive binder layer.

Asphalt Reinforcement Services Ltd, Ringway and Material Edge Ltd. UK representative of Ooms Avenhorn Holding, the manufacturer of Sealoflex SC-33 (now SC-4). The registered owners of the GridSeal® are responsible for the spraying of Sealoflex SC-33 (now SC-4). This specialist binder requires a specialised surface dressing spray tanker that can spray highly polymerised binders at up to 200°C.

For this project Ooms Avenhorn Holding contractor arm Ooms Producten provided sub-contracted supply and laying of the Sealoflex SC-33 to Asphalt Reinforcement Services.

On the first visit approximately 11,000m² of GlasGrid® was laid with a special laying machine by ARS Ltd in about five hours the day before the Sealoflex SC-33 was laid. Overnight rain did not affect the grid which remained adhered to the surfacing through its contact adhesive. The surface was dry by the morning and spraying of the hot PMB took about three hours with chipping a further two hours.

The chippings keep the paving traffic away from the highly adhesive binder layer and provide an excellent key into the overlay which in this case was a 10mm SMA specification design to provide good skid resistance and low scuffing under power assisted steering from parking cars.

The asphalt overlay design provides a smooth well drained surface for car parking over an area of concrete including some spalled joints and fractured PCC slabs that was previously Heathrow Airport taxiway. Commencing with a layer of approximately 20mm of regulating onto which the GridSeal® system is applied the whole area is being overlaid with 40mm minimum thickness of SMA surfacing by the main contractor Ringway.

On our most recent visit to the Pink Elephant Car Park in 2013 a thorough examination of the surfacing showed some areas of fretting on corners where traffic was turning. There were isolated cracks showing in one area at the top of the project where it is believed GridSeal was missing from the pavement, however the total amount of cracking on the project reflects a very small % of the concrete bay joints underneath the 40mm overlay, a considerable achievement after 9 years performance of such a thin overlay. Next time you fly from Heathrow take a look yourself at the Pink Elephant Car Park.

Tags: Sealoflex

Posted by Neil Jones on Saturday, 07 June 2014 at 10:00:12

Filed under: General

Welcome!

Welcome to our new website. Find out more about our products and services and contact us today.

Tags:

Posted by Chris Sullivan on Friday, 06 June 2014 at 14:58:59

Filed under: Products, Case Studies

Bob Noakes of Norfolk County Council, Howard Cooke of Asphalt Reinforcement Services and Chris Sullivan of Material Edge visited a variety of sites to see the Dutch experience of the long term performance of GridSeal®.

System Properties

GridSeal® is a composite reinforcing system developed by Ooms Avenhorn Holding bv, consisting of GlasGrid® glassfibre reinforcement mesh and a hot sprayed Sam-C® membrane of SBS polymer modified bitumen. Depending on the circumstances GlasGrid® is covered with 1.0 to 2.5kg/sq.m of hot sprayed Sealoflex®-SC 4 and then treated with approximately 7kg/sq.m. of clean crushed aggregate.

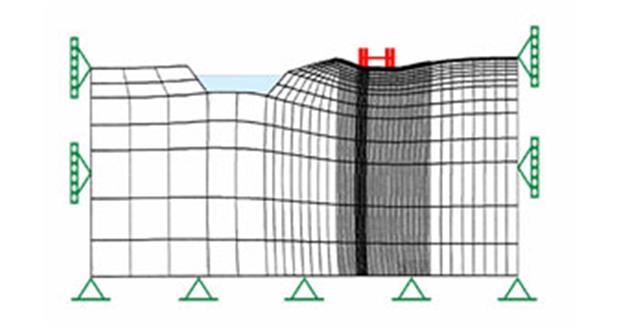

Modelling loading on peat roads

Benefits of Gridseal®

GridSeal® provides improved protection against reflective cracking; excellent and durable visco elastic bond between the existing pavement and the new overlay; durable and tough anchorage of the reinforcement giving increased performance; superior interlock; durable waterproofing of the underlying pavement structure.

Site Visits

The first site visit was to the N99, in the area of Den Helder a 50 years old concrete road overlaid with GridSeal® and Sealoflex® asphalt in 1993. The pavement structure is 18 cm concrete, Sealoflex asphalt levelling course, GridSeal consisting of GlasGrid 8501 and 2.5 kg/m2 Sealoflex®-SC 4, 4 cm dense asphalt concrete and 5 cm porous asphalt.

This site was like many others in The Netherlands boarded on 2 sides by water. On the north side the road runs parallel with a cycle path which is next to a 4metre high dyke behind which is the North Sea. On the south side the road forms the embankment and 1metre below is polder land with irrigation and drainage channels. The road structure therefore is surrounded by and founded on water.

The GridSeal® was chosen in this location for its ability to prevent reflective cracking from settlement cracking which occurs in the pavement structure as a result of swelling and shrinkage during winter and summer conditions. The combination of GlasGrid® reinforcement for strength and Sealoflex® SC 4 for waterproofing has performed admirably with no obvious cracking appearing along the treated section. Sealoflex® in the surfacing layers has prevented any rutting as well as keeping the surfacing durable and crack free. The road texture is still excellent and intervention through overlay has not been necessary during the 12 year life. The pavement looked as if it would last another 12 years without maintenance being required.

On the following day the group visited Mr. Nills Strijbos of Hoogheemraadschap Hollands Noorderkwartier in the area of Amsterdam where he together with Ruud Talsma of Ooms Construction bv showed on their area maps the variety and scope of sites now using Gridseal® for more than 10 years. Mr. Strijbos explained that all of the fully flexible highways in his area which are subject to settlements due to water movement have in the past been heavily patched every 2-5 years. However where GridSeal® is used lifetimes of 8 to 10 years plus are common. All new sites which are in areas subject to settlement are now provided with GridSeal® treatment to prevent premature failure.

There then followed a series of site visits including to one site where GlasGrid® reinforcement alone had been used in the early days and which was showing earlier signs of deterioration than the GridSeal® combination sites.

In addition some failed sites were visited to show the type of failure that occurred where GridSeal® is not used. These failures were similar to many of the peat and fen road sites seen in the UK and Ireland which was of particular interest to Bob Noakes for the areas of England around Norfolk and Suffolk where there are many similar problems encountered.

One particular site where trees were along one side on a small embankment which dropped into drainage channels there were signs of cracking. This was thought to be due to the excessive water demands of the trees and patching using GridSeal® had been performed in those areas with great success.

All told the history of use of GridSeal® was one of success and Mr. Strijbos intended to use the system for a long time to come.

Tags: gridseal, dutch

Posted by Chris Sullivan on Tuesday, 03 June 2014 at 14:58:33

Filed under: Products, Case Studies

Background to M11 Asphalt Reinforcement Trials

Traffic Data

The results show the 20-year predicted traffic loading in lane 1 and lane 2 to be 83msa and 19msa respectively.

Contractor and design life

The successful contractor was La Farge. The design life requirements for the trial section are 20 years.

Programme of works for trial area

GridSeal® trials of 210linear metres (936sq.m.) were installed between chainages 2990 and 3110 on the M11 Southbound Junctions 10 to 9 in the early morning of Thursday 8th November 2007. The installation commenced at 12.00am and finished at 12.31am.

Present during laying by Asphalt Reinforcement Services were Howard Cooke and Ian Walker of ARS and Chris Sullivan of Material Edge Ltd. Also in attendance were TRL representatives.

Treatment in the Hard shoulder was not part of the trial. The surface was planed down 60mm and 25mm of regulating was put back followed by 40mm surface course.

Treatment in Lanes 1 and 2 GridSeal® trials

The weather throughout laying was dry and cool (about 5°C), the surface was swept clean using wet and dry vacuum road sweepers.

Plane off 110-115mm of existing asphalt leaving about 30mm over the CBM and sweep clean. Replaced with:

During laying the chipping lorry damaged a small 1m x 2m section of the GridSeal® resulting in an area of pad coat and GridSeal being removed and replaced by hand. This was located in the centre of lane 2 at Chainage 2990. The repair was installed to the satisfaction of those supervising.

Otherwise there were no observed difficulties in installation over subsequent overlaying of the GridSeal® system.

View more information about GridSeal®.

Tags: asphalt, trial, highways

Posted by Chris Sullivan on Friday, 30 May 2014 at 10:00:24

Filed under: Products, Case Studies

The use of asphalt to generate solar heated water to defrost roads is an excellent subject for NCE to bring to the attention of your readers. In addition to the TRL trials using soil as the medium of storage (Trials begin on salt free road de icing system NCE last week) there is already a commercially available system being used in The Netherlands which utilises ground water in aquifers for storage of hot and cold water.

The first 2 Road Energy System® projects (as the Dutch process is called) in the UK are now imminently being constructed in Scotland by a soon to be signed UK licensee. A national surfacing contractor has also expressed interest in the system which utilises low temperature polymer modified asphalts to avoid melting the European patented plastic pipes and retaining grid system.

Undoubtedly interest will continue to grow when people fully realise the scope for generating heat and cold from asphalt pavements.

The Road Energy System® was developed jointly by a multi discipline engineering team comprising Ooms Avenhorn Holding (contractor), Tipspit and Vloerverwarming as a method for heating and cooling buildings. Following this process the ‘waste’ warm and cold water still has sufficient energy to defrost in winter roads, car parks, ramps, flyovers, aircraft standing and taxiways etc as well as cooling them during summer, thus prolonging the life of the pavement into the bargain. The system has successfully passed through extensive trials and developments over the last 8 years to reach major scheme status. The largest project to date at 10,000sq.m. is a flyover into Rotherdam docks where defrosting of the elevated structure is key to ensuring year round access.

Now that authorities and clients are looking to new housing, airport and industrial developments to be carbon neutral in terms of environmental impact the Road Energy System® provides a viable proven solution to low energy heating and cooling of buildings. Forward looking councils like Dundee have already identified schemes where the system maybe used in future. Airport authorities have also expressed interest with acres of black surfacing to utilise for collecting energy, which also require defrosting in winter, and large terminal buildings to heat and cool.

With NCE’s talent to reach the masses we would be delighted to show your readers real European cooperation involving multi disciplined engineering teams on UK based working projects in the near future.

Chris Sullivan I Eng.,M.I.H.T.

Managing Director

Material Edge Ltd

Tags: salt, trials