Posted by Chris Sullivan on Friday, 12 June 2015 at 13:44:02

Filed under: Bitumen

The idea behind SolaRoad is simple: sunlight falling on the road surface is absorbed by solar cells and converted into electricity – the road surface acts as a large solar panel. The electricity generated in this way will find practical applications in street lighting.

Read more here. and here.

Tags: ooms

Posted by Chris Sullivan on Friday, 12 June 2015 at 13:42:35

Filed under: Bitumen

A new primary school in Hampshire has applied over 1500 square metres of Bituchem's Natratex Cotswold to its playground and outdoor teaching areas.

Berewood Primary School accomodates children aged four to eleven.The Natratex Cotswold material was specified in buff as it was considered more attractive than black tarmac but still smooth enough to be safe for young children to play on.

Read the full article here.

Tags: playground

Posted by Chris Sullivan on Tuesday, 21 April 2015 at 18:10:16

Filed under: Bitumen

Hard landscaping specialists, Bituchem has completed the first application of its advanced Natratex Cotswold Porous material at the recently redeveloped Royal William Yard in Plymouth. Approximately 2000sq.m of the porous material was applied to the ‘secret garden’ car park, giving both a practical and aesthetically pleasing finish to the site.

Designed by Dartington-based Gillespie Yunnie Architects the new car park is situated within a number of Grade II listed walls, formerly a Grade I listed Nursery Walled Garden. The 140-space car park has used Bituchem’s Natratex Cotswold Porous material as well as real grass with plastic trays for reinforcement, to give the entire car park a natural drainage system.

Will Hoare, architect at Gillespies Yunnie, commented. “Due to the nature of the site there were some planning restrictions put in place with the design of the new car park in terms of appearance and sustainability. It was particularly important that the new car park maintained the natural aesthetics of the Nursery Garden without using normal drainage systems. We found that Bituchem’s Natratex Cotswold Porous material offers a solution to both of these requirements and we are really pleased with the outcome.”

The Natratex Cotswold Porous material is particularly suitable for applications on sites with preservation restrictions, due to the lack of deep earth work needed. This also makes the application and maintenance of the material significantly easier than other infiltration systems. The application does not require any additional drainage systems which reduces the overall time and cost of the project.

Bituchem re-designed its popular Natratex Cotswold material to replicate natural infiltration methods, in response to the demand for Sustainable Drainage Systems (SuDS). The asphalt material is laid on a porous receiving layer and has an open structure to allow water to permeate through the surface into the ground and eventually finding its way to a natural water source. The material has been designed to remove the need for conventional drainage systems, thus eliminating the likelihood of blocked drains and water contamination.

Natratex Cotswold Porous is suitable for areas that see pedestrian and light vehicular use and are susceptible to flooding, such as car parks, footpaths, recreational parks and residential roads. The material is crafted using colour co-ordinated aggregate and pigments available in a range of colours, combined with a clear binder to provide an attractive and durable hard landscaping surface.

The new car park at the Royal William Yard is just one part of the redevelopment of the Plymouth landmark led by developers, Urban Splash. The project has been taking place for a number of years and has introduced a range of commercial, residential and leisure areas, including a large variety of restaurants, making it the perfect socialising environment for locals and tourists.

Tags: bitumen

Posted by Chris Sullivan on Wednesday, 21 January 2015 at 19:00:12

Filed under: Bitumen

Ooms launch new Web site covering their extensive offerings in pavement design; supply, manufacture and licensee arrangements for Sealoflex polymer modified bitumens. Visit www.oomspmb.nl for more details.Tags: ooms, website

Posted by Chris Sullivan on Friday, 06 June 2014 at 14:58:59

Filed under: Products, Case Studies

Bob Noakes of Norfolk County Council, Howard Cooke of Asphalt Reinforcement Services and Chris Sullivan of Material Edge visited a variety of sites to see the Dutch experience of the long term performance of GridSeal®.

System Properties

GridSeal® is a composite reinforcing system developed by Ooms Avenhorn Holding bv, consisting of GlasGrid® glassfibre reinforcement mesh and a hot sprayed Sam-C® membrane of SBS polymer modified bitumen. Depending on the circumstances GlasGrid® is covered with 1.0 to 2.5kg/sq.m of hot sprayed Sealoflex®-SC 4 and then treated with approximately 7kg/sq.m. of clean crushed aggregate.

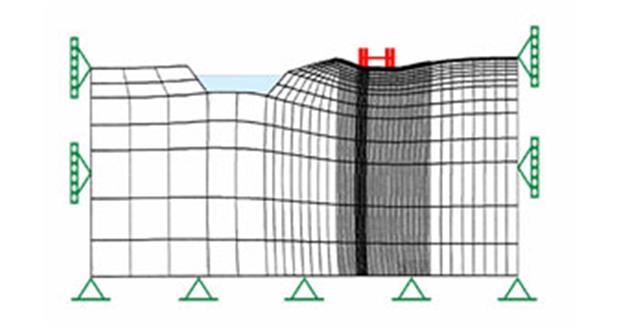

Modelling loading on peat roads

Benefits of Gridseal®

GridSeal® provides improved protection against reflective cracking; excellent and durable visco elastic bond between the existing pavement and the new overlay; durable and tough anchorage of the reinforcement giving increased performance; superior interlock; durable waterproofing of the underlying pavement structure.

Site Visits

The first site visit was to the N99, in the area of Den Helder a 50 years old concrete road overlaid with GridSeal® and Sealoflex® asphalt in 1993. The pavement structure is 18 cm concrete, Sealoflex asphalt levelling course, GridSeal consisting of GlasGrid 8501 and 2.5 kg/m2 Sealoflex®-SC 4, 4 cm dense asphalt concrete and 5 cm porous asphalt.

This site was like many others in The Netherlands boarded on 2 sides by water. On the north side the road runs parallel with a cycle path which is next to a 4metre high dyke behind which is the North Sea. On the south side the road forms the embankment and 1metre below is polder land with irrigation and drainage channels. The road structure therefore is surrounded by and founded on water.

The GridSeal® was chosen in this location for its ability to prevent reflective cracking from settlement cracking which occurs in the pavement structure as a result of swelling and shrinkage during winter and summer conditions. The combination of GlasGrid® reinforcement for strength and Sealoflex® SC 4 for waterproofing has performed admirably with no obvious cracking appearing along the treated section. Sealoflex® in the surfacing layers has prevented any rutting as well as keeping the surfacing durable and crack free. The road texture is still excellent and intervention through overlay has not been necessary during the 12 year life. The pavement looked as if it would last another 12 years without maintenance being required.

On the following day the group visited Mr. Nills Strijbos of Hoogheemraadschap Hollands Noorderkwartier in the area of Amsterdam where he together with Ruud Talsma of Ooms Construction bv showed on their area maps the variety and scope of sites now using Gridseal® for more than 10 years. Mr. Strijbos explained that all of the fully flexible highways in his area which are subject to settlements due to water movement have in the past been heavily patched every 2-5 years. However where GridSeal® is used lifetimes of 8 to 10 years plus are common. All new sites which are in areas subject to settlement are now provided with GridSeal® treatment to prevent premature failure.

There then followed a series of site visits including to one site where GlasGrid® reinforcement alone had been used in the early days and which was showing earlier signs of deterioration than the GridSeal® combination sites.

In addition some failed sites were visited to show the type of failure that occurred where GridSeal® is not used. These failures were similar to many of the peat and fen road sites seen in the UK and Ireland which was of particular interest to Bob Noakes for the areas of England around Norfolk and Suffolk where there are many similar problems encountered.

One particular site where trees were along one side on a small embankment which dropped into drainage channels there were signs of cracking. This was thought to be due to the excessive water demands of the trees and patching using GridSeal® had been performed in those areas with great success.

All told the history of use of GridSeal® was one of success and Mr. Strijbos intended to use the system for a long time to come.

Tags: gridseal, dutch